Stock Changes Documentation

Child Part Definition in Part Master

In the Part Master, there is a Child Parts sub-tab where you can define which child parts are required to produce a parent part, along with the required quantity.

Example:

- Part A is a parent part.

- It has two child parts:

- Child 01 – Required quantity: 2

- Child 02 – Required quantity: 3

These quantities are defined in the Child Parts sub-tab of the Part Master.

Child Part Consumption in Control Plan

We are introducing a new sub-tab called Child Part Consumption under the Control Plan tab.

This tab allows users to define how much of each child part should be reduced from the main inventory after completing specific processes.

Example: Control Plan for Part A

The Control Plan for Part A consists of the following processes:

- Inward

- Inward Inspection

- Milling 1

- Milling 2

- Milling 3 (Final Machining)

- Final Inspection

Child Part Consumption Mapping Example:

- Child 01 (Total Required: 2)

- Milling 1 → 1 quantity

- Milling 2 → 1 quantity

- Child 02 (Total Required: 3)

- Milling 1 → 3 quantities

This means:

- After completing Milling 1, reduce 1 unit of Child 01 and 3 units of Child 02 from inventory.

- After completing Milling 2, reduce 1 more unit of Child 01 from inventory.

- This definition is not to indicate how or where each child part is physically used in the production process.

- It is purely to define when and how much of each child part should be deducted from inventory based on the process.

- For example, if Child 01 is used in multiple processes (Milling 1, Milling 2, Milling 3), we should not assign it to all processes.

- Its total required quantity is only 2.

- Assigning it to every process would result in over-consumption from inventory.

Production Stock Movement Flow Documentation

1. Part Setup in the System

Parent Part (Sale Order Part):

SALE P - Part A

Child Part (Used in Manufacturing):

CASTING C - Part A- Defined in Part Master → Child Tab

- Required Quantity: 1

2. Control Plans Configuration

| Control Plan ID | Part | Processes |

|---|---|---|

| CP/001/SP | SALE P - Part A | Inward, Inward Inspection, Milling 1, Milling 2, Milling 3, Final Inspection |

| CP/001/CP | CASTING C - Part A | Inward, Inward Inspection |

Child Part Consumption Defined in CP/001/SP (SALE P - Part A):

- CASTING C - Part A

- Milling 1 → 1 qty consumption

3. Production Scenario: Sale Order Received

Initial Stock:

- SALE P - Part A: 0

- CASTING C - Part A: 0

Customer Sale Order Quantity: 1

Action:

- Purchase CASTING C - Part A from the supplier.

- After purchase and processing through:

- Inward

- Inward Inspection

→ Batch is generated for CASTING C - Part A.

Updated Stock:

- CASTING C - Part A: 1

- SALE P - Part A: 0

4. Manufacturing Using Control Task

- Navigate to:

Production & Quality → Operation → Control Task - Select Control Plan:

CP/001/SPfor SALE P - Part A - Start Process:

Milling 1 (Initial Machining)

System Action:

- Child batch is linked (CASTING C - Part A).

- Serial numbers generated for batch.

- Ready to start manufacturing.

5. Process-Wise Stock Changes

Milling 1

- If part status is Approved or Rejected:

- Reduce CASTING C - Part A stock by 1 qty

- Entry made in consumption table with Type:

PROD

- If status is Hold for Inspection, Rework, or Machining Defect:

- No stock update

Stock after Milling 1:

- CASTING C - Part A: 0

- SALE P - Part A: 0

Milling 2

- No child part consumption defined.

- No stock changes, regardless of part status.

Stock remains:

- CASTING C - Part A: 0

- SALE P - Part A: 0

Milling 3 (Final Machining)

- No child part consumption defined.

- Final machining stage completed.

System Action:

- Increase SALE P - Part A stock by 1 qty

- Entry made in Production Inward table.

Stock after Milling 3:

- CASTING C - Part A: 0

- SALE P - Part A: 1

Final Inspection

- No stock changes.

6. Invoicing (After Finished Good is Ready)

- Invoice raised against SALE P - Part A for customer.

System Action:

- Reduce SALE P - Part A stock by 1 qty

- Entry made in inventory with Type:

PROD

Final Stock:

- CASTING C - Part A: 0

- SALE P - Part A: 0

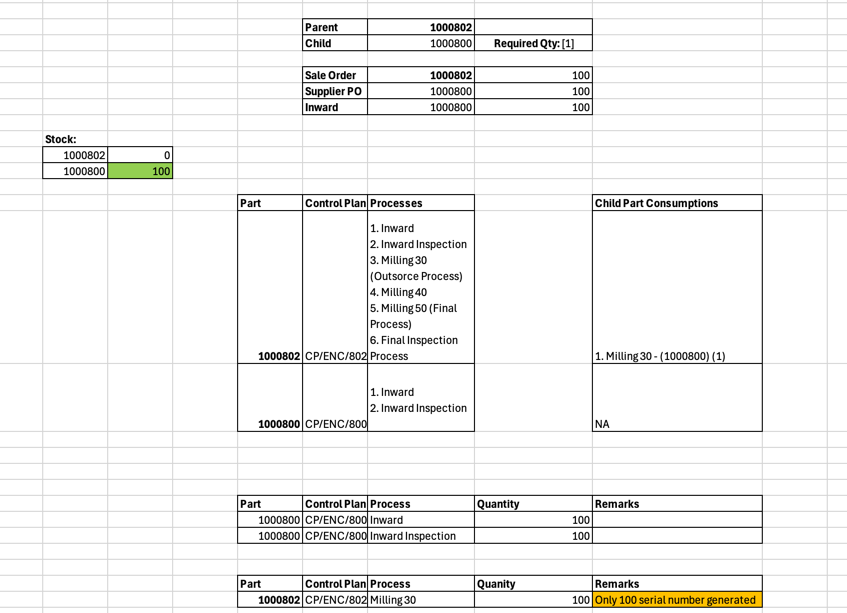

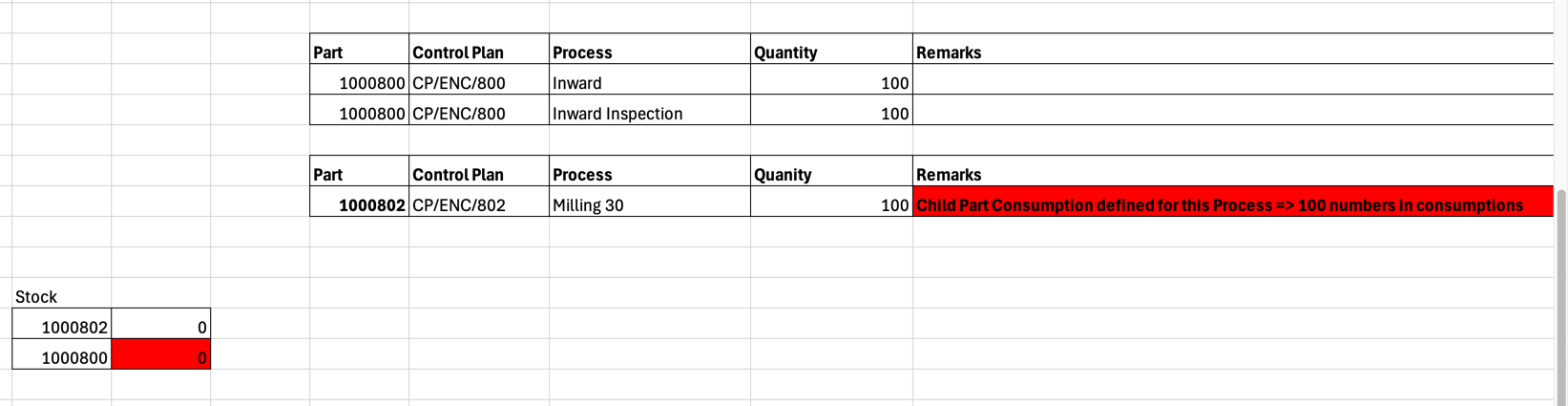

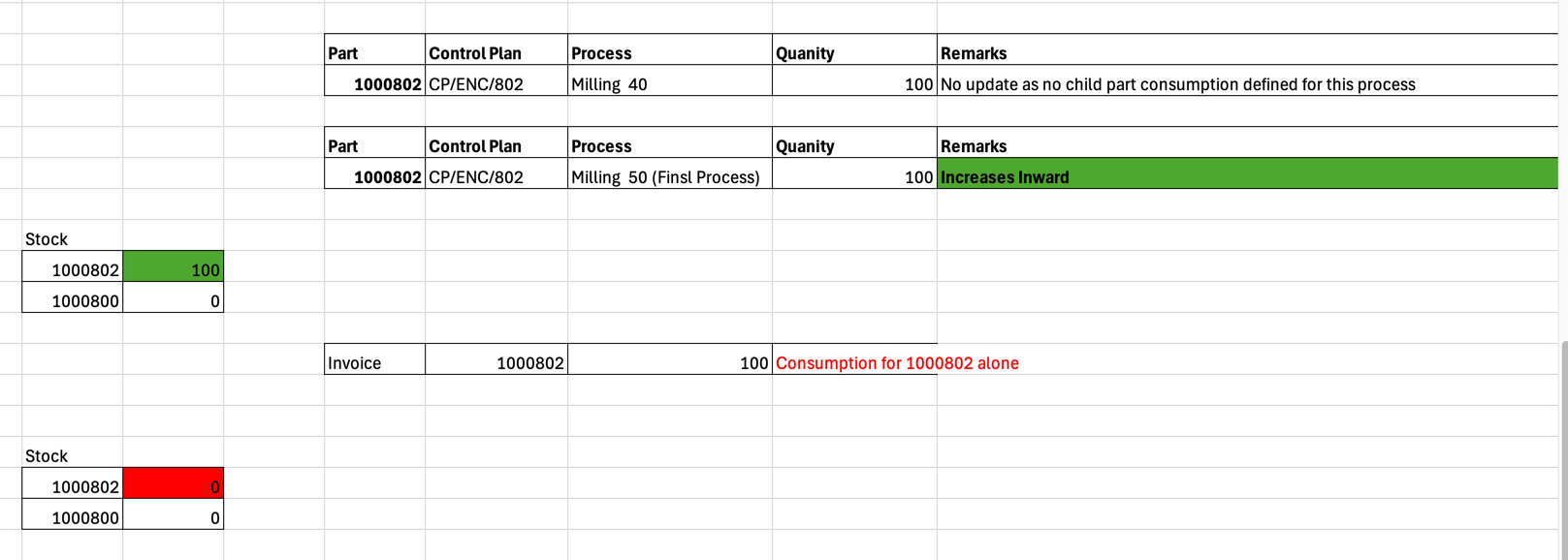

Sample Flow 1:

Part - Child relation:

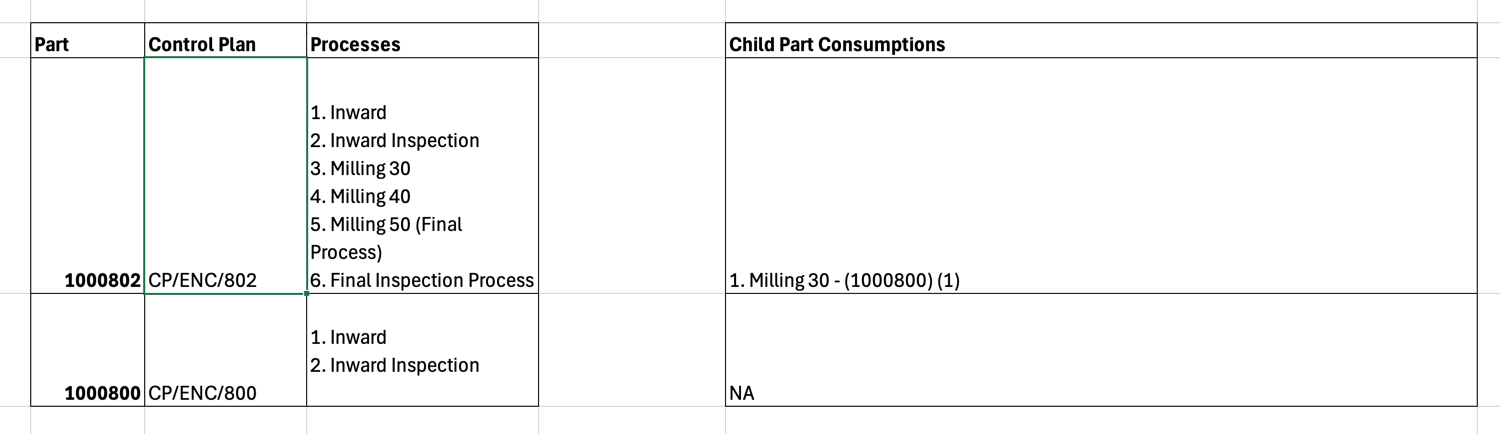

Control Plan and Child Part Consumptions:

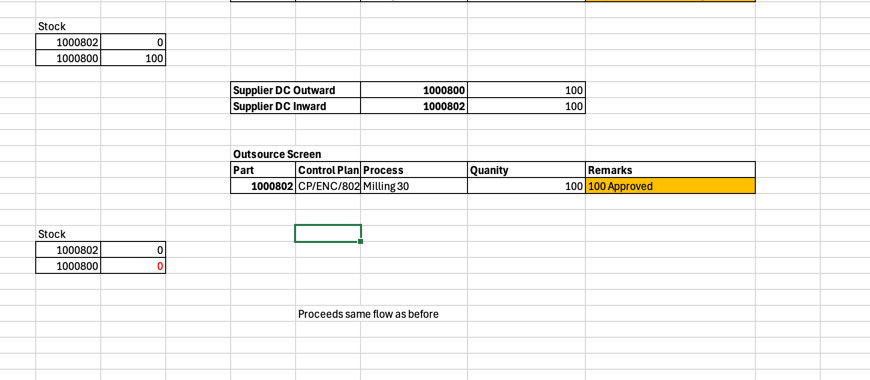

Stock handling in production:

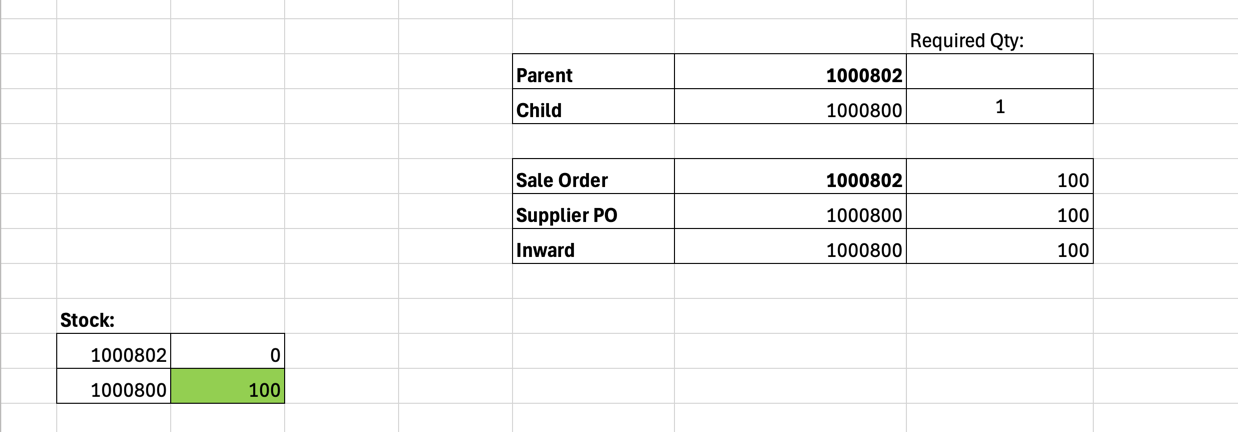

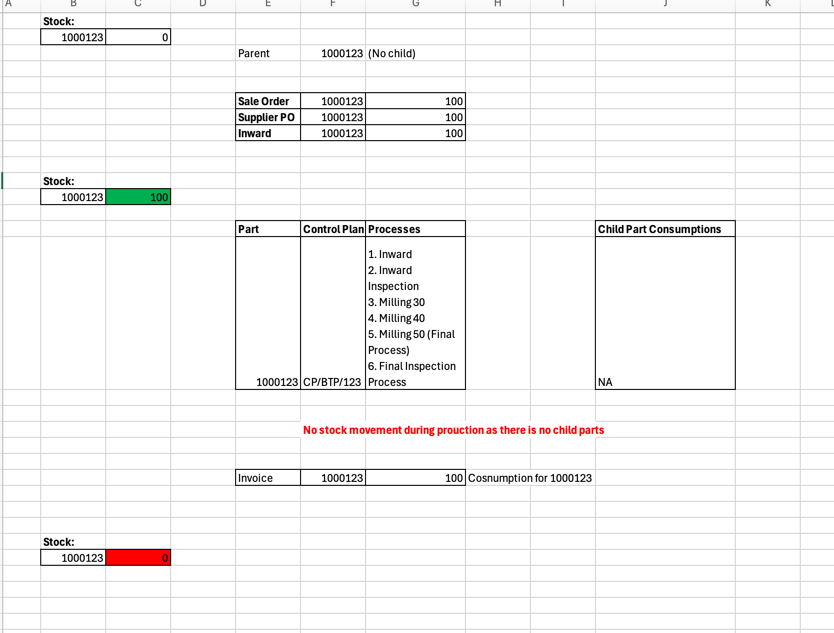

Sample Flow 2:

Part without child:

Outsourcing Part: